-

Fil d’actualités

- EXPLORER

-

Pages

-

Groupes

-

Blogs

-

Forums

Why Crystal Awards Remain Relevant Across Industries

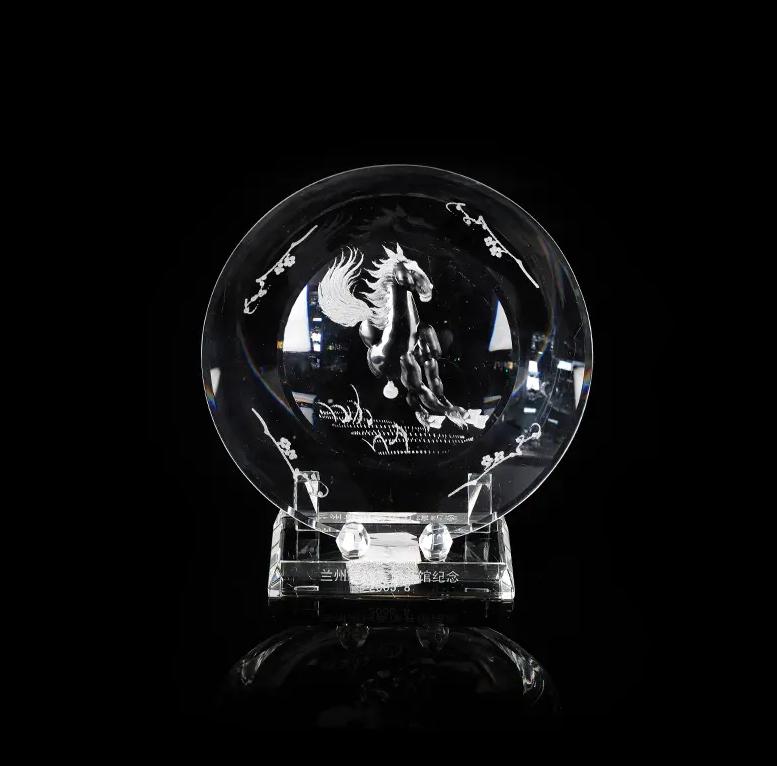

A Crystal Laser Ball is often designed with long-term display in mind. When produced by a Crystal Glass Award Factory, the focus extends beyond immediate visual appeal to include durability, clarity retention, and ease of maintenance. These characteristics make crystal laser balls suitable for environments where awards are expected to remain on display for extended periods, such as offices, showrooms, or institutional spaces.

Long-term display requires materials that resist visible aging. Crystal glass, when properly processed, maintains transparency and surface smoothness over time. Internal laser engravings are protected from physical contact, reducing the risk of wear compared to surface-printed designs. This internal placement ensures that logos and text remain legible even after years of exposure to light and handling.

Across industries, recognition practices share common needs despite differing contexts. Manufacturing firms, educational institutions, and service organizations all use awards to acknowledge contribution and progress. Crystal laser balls adapt to these varied uses by offering a neutral yet refined form. Their lack of industry-specific imagery allows them to be customized through engraving rather than structural changes.

Design trends within the award industry have gradually shifted toward simplicity and material honesty. Instead of complex shapes or mixed materials, many buyers now prefer designs that emphasize craftsmanship. Crystal Glass Award Factories respond to this trend by refining polishing techniques, improving engraving resolution, and offering subtle design enhancements rather than dramatic alterations.

Another trend involves personalization at scale. Organizations want awards that feel individual without creating excessive production complexity. Laser engraving technology supports this by allowing variable text or imagery within a standardized crystal form. A crystal laser ball can accommodate different names or achievements while maintaining consistent external dimensions and finish.

Lighting considerations also influence design decisions. Many crystal awards are displayed under office lighting rather than spotlight conditions. Internal engravings must be visible under moderate light levels without relying on dramatic contrasts. Factories may adjust engraving density or point spacing to ensure clarity under everyday lighting conditions.

Supply chain stability has become a factor in sourcing decisions. Buyers increasingly value factories that maintain steady material sourcing and production capacity. A Crystal Glass Award Factory with established processes can manage both small custom orders and larger recurring projects without compromising consistency.

As workplaces place greater emphasis on meaningful recognition, the physical form of awards continues to matter. Crystal laser balls support this emphasis by offering a calm, balanced presence that does not compete with surrounding decor. Their visual restraint allows the engraved message to carry significance without distraction.

Looking ahead, crystal awards are likely to continue evolving through incremental improvements rather than radical redesigns. Advances in engraving precision and quality control will further refine how internal details are rendered. Crystal laser balls, supported by the capabilities of experienced Crystal Glass Award Factories, remain well-positioned to meet ongoing recognition needs through thoughtful design and dependable craftsmanship.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness