-

Nieuws Feed

- EXPLORE

-

Pagina

-

Groepen

-

Blogs

-

Forums

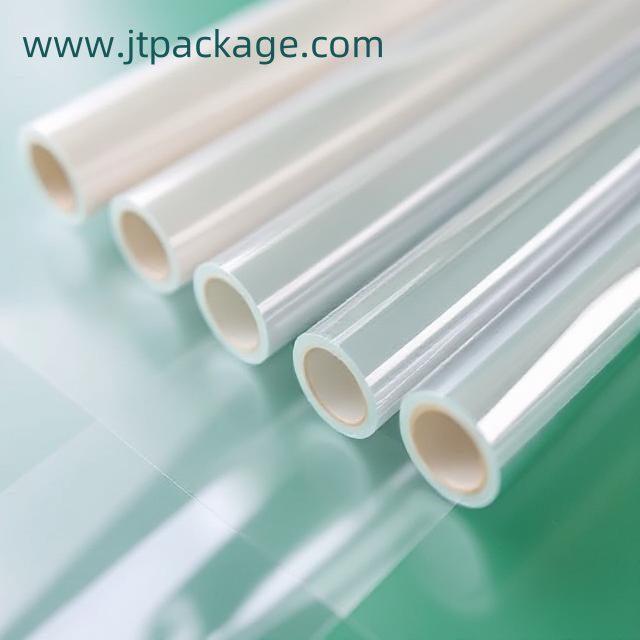

Crosslinked Shrink Film Performance for Stable Packaging Presentation

Modern packaging continues to evolve as businesses seek materials that deliver strength, clarity, and controlled performance throughout handling stages. Crosslinked Shrink Film is often referenced within this discussion because it supports stable wrapping while maintaining a refined appearance. Its structure allows packages to hold form securely, creating a smooth outer layer that enhances presentation without unnecessary bulk.

A defining characteristic of this material is its balanced response during shrinking. The surface tightens evenly, allowing wrapped items to maintain natural contours rather than appearing forced or distorted. This controlled behavior supports reliable sealing and helps packages retain a clean outline during movement, storage, and display. Consistency at this stage plays an important role in maintaining professional presentation.

Flexibility combined with resilience supports daily packaging operations. The material adapts around edges and grouped products while maintaining surface integrity. Gentle stretch behavior helps prevent tearing during application, allowing packaging teams to work efficiently without frequent interruptions. This balance between adaptability and strength contributes to smoother workflows across varied packaging environments.

Visual quality remains an important factor for many products. Clear wrapping allows contents to remain visible, supporting trust and transparency between brand and buyer. A clean surface also supports label readability, ensuring essential information remains easy to view. Presentation that feels orderly and intentional can influence perception before direct interaction occurs.

Handling durability adds further value. During lifting, stacking, or routine transport, the outer layer maintains structure and resists minor surface contact. This reliability reduces the likelihood of rewrapping, helping operations remain consistent and efficient. Stable protection throughout movement supports confidence across supply chains without adding unnecessary complexity.

Operational predictability supports planning and efficiency. When material behavior remains consistent, teams can refine processes with fewer adjustments. Predictable results help maintain uniform appearance across packaging runs while supporting resource efficiency. Reliable wrapping performance allows both small operations and broader distribution activities to maintain quality standards.

Environmental awareness has also shaped packaging preferences. Materials that provide effective coverage without excess thickness align with modern expectations around responsible use. A balanced structure allows protection while minimizing unnecessary material presence. This approach supports thoughtful packaging choices while maintaining dependable performance.

Brand presentation benefits from a polished outer layer. Smooth surfaces support clean labeling and a professional finish that reflects attention to detail. When packaging quality aligns with product value, it reinforces credibility and care. Subtle elements such as tight edges and uniform finish can shape positive impressions before products are opened or used.

Selecting appropriate packaging materials requires understanding behavior, appearance, and operational impact. Informed decisions help align protection with presentation goals while supporting efficient workflows. Guidance from experienced sources can assist businesses seeking dependable solutions. For further insight and contextual reference, information is available through JTPACKAGE, with additional details provided through the following resource https://www.jtpackage.com/news/industry-news/crosslinked-shrink-films-an-innovative-force-in-packaging.html

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness