Compliance Testing: Ensuring Safety, Quality, and Regulatory Standards

In today’s fast-paced technological world, compliance testing plays a crucial role in ensuring that products meet regulatory standards, function safely, and are market-ready. Whether you are in electronics, medical devices, telecommunications, or industrial equipment, compliance testing ensures your product adheres to local and international regulations, protecting both consumers and manufacturers.

What is Compliance Testing?

Compliance testing, also known as conformity assessment, is the process of verifying whether a product, system, or component meets a set of predefined regulatory, safety, or performance standards. It involves testing against government regulations, industry standards, and technical specifications.

This testing can cover various aspects, including:

-

Electrical safety – Ensuring the device operates safely without risk of electric shock or fire.

-

Electromagnetic compatibility (EMC) – Confirming that electronic devices do not emit harmful electromagnetic interference (EMI) and are immune to interference from other devices.

-

Environmental compliance – Verifying adherence to standards like RoHS, WEEE, and REACH, ensuring that products are environmentally friendly.

-

Performance and functional testing – Ensuring that the product works as intended under normal and extreme conditions.

Importance of Compliance Testing

-

Legal Compliance – Many countries require products to pass compliance tests before they can be sold. Failing to comply can lead to fines, product recalls, or bans.

-

Consumer Safety – Compliance testing ensures that products are safe to use, reducing risks such as electrical hazards, chemical exposure, or mechanical failure.

-

Market Access – Passing compliance testing is often a prerequisite for global market entry, especially in regions like the EU (CE marking), USA (FCC), or Canada (IC certification).

-

Brand Reputation – Products that meet compliance standards build trust and credibility with consumers and business partners.

Types of Compliance Testing

1. Electrical Safety Testing

Electrical safety testing verifies that a device operates without risk of injury or fire. Standards like IEC 60950, IEC 61010, or UL 62368 are commonly used depending on the product type.

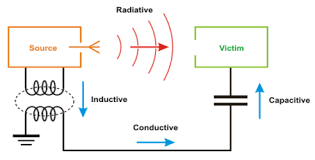

2. EMC (Electromagnetic Compatibility) Testing

EMC testing ensures devices do not cause or suffer from electromagnetic interference. This includes:

-

Emission Testing – Measuring electromagnetic energy emitted from a device.

-

Immunity Testing – Assessing how devices perform when exposed to electromagnetic interference.

3. Environmental Compliance Testing

Products are tested for hazardous substances and environmental impact, ensuring adherence to regulations like:

-

RoHS (Restriction of Hazardous Substances)

-

WEEE (Waste Electrical and Electronic Equipment)

-

REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals)

4. Functional and Performance Testing

This includes testing the product under normal and extreme conditions to ensure durability, efficiency, and performance.

Compliance Testing Process

The typical compliance testing process involves several stages:

-

Requirement Analysis – Identifying relevant regulations and standards for the product.

-

Pre-Testing/Pre-Compliance – Early tests to catch potential failures before full testing.

-

Laboratory Testing – Conducting formal tests in accredited laboratories.

-

Certification – Issuing a compliance certificate or mark for products that pass all tests.

-

Continuous Monitoring – Periodic audits and retesting to maintain compliance throughout production.

Choosing the Right Compliance Testing Lab

Selecting a reputable and accredited compliance testing lab is critical. Key factors include:

-

Accreditation (ISO/IEC 17025, FCC, CE, UL, etc.)

-

Expertise in specific industries or product types

-

Testing capabilities and equipment

-

Fast turnaround time and detailed reporting

Conclusion

Compliance testing is more than a regulatory requirement—it’s a commitment to safety, quality, and consumer trust. By investing in thorough compliance testing, businesses not only protect themselves from legal and financial risks but also strengthen their brand reputation and access global markets confidently.

Whether you are launching a new electronic device, industrial equipment, or consumer product, compliance testing ensures your product meets international standards and delivers safe, reliable performance.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness