Why PVC Ceiling Films Are the Future of Home Design

PVC Ceiling Film have become an essential choice in modern construction and interior design due to their durability, flexibility, and aesthetic appeal. These films, made from high-quality polyvinyl chloride (PVC), offer a perfect balance of strength and versatility, making them ideal for various ceiling applications. In this article, we will explore the material properties, production process, key performance characteristics, and wide range of uses for these films, with a special focus on how Shanghai MSD manufactures and delivers top-quality products to meet the demands of today’s markets.

PVC ceiling films are produced by combining high-grade PVC resin with plasticizers, stabilizers, and other additives to achieve an optimal blend of flexibility and rigidity. The material exhibits excellent tensile strength and resistance to moisture, making it highly durable even in environments with varying temperatures and humidity. One of the key advantages of PVC is its ability to withstand prolonged exposure to sunlight without experiencing significant degradation. This makes it an excellent choice for areas where the ceiling is exposed to light or harsh weather conditions.

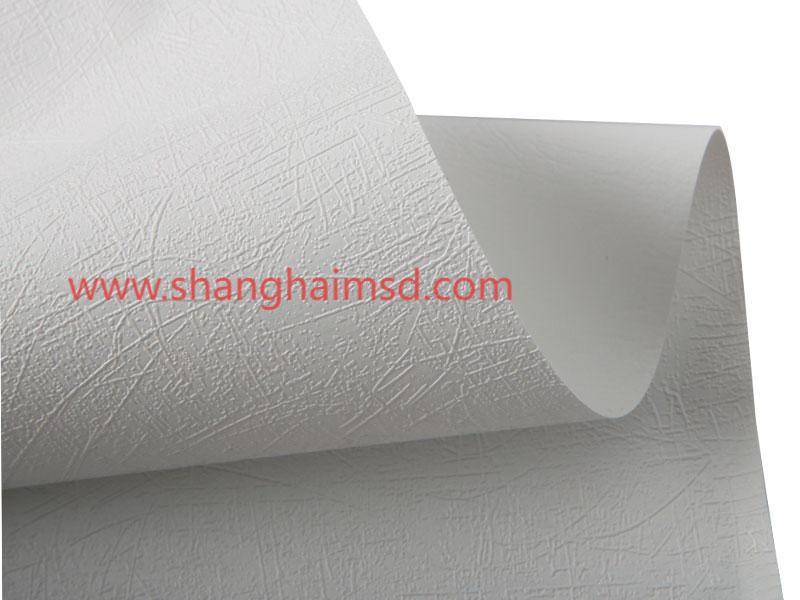

In addition to its physical durability, PVC ceiling films are non-toxic, recyclable, and flame-retardant, making them safe for both residential and commercial use. They can also be customized with various textures, colors, and finishes to meet the specific design requirements of a space. Whether a matte, glossy, or embossed finish is required, these films can be tailored to fit a wide array of aesthetic preferences.

The manufacturing process of PVC ceiling films involves several steps to ensure the highest quality standards are met. The first step is the extrusion of PVC resin, where the material is heated and passed through a die to create a continuous sheet. This sheet is then cooled and stretched to the desired thickness. Shanghai MSD employs advanced extrusion and calendaring technologies to produce films with consistent thickness, high clarity, and minimal defects.

After the film is formed, it goes through additional processes, such as surface treatment and lamination, to enhance its performance. Surface treatments are used to improve the film’s adhesion to other materials, such as adhesives or coatings, while lamination allows for the application of decorative finishes. Shanghai MSD uses state-of-the-art techniques to ensure the final product is of the highest quality, with close attention paid to surface finish and consistency.

The performance of PVC ceiling films is evaluated through a series of rigorous tests to ensure they meet industry standards. These tests evaluate characteristics such as UV resistance, fire retardancy, moisture resistance, and flexibility. UV resistance is particularly important for ceiling films that are exposed to sunlight, as it ensures that the film maintains its color and structural integrity over time. Fire retardancy is another essential property, as the film must not contribute to the spread of flames in the event of a fire. Additionally, flexibility tests ensure that the material can handle installation and perform well under various environmental conditions.

These films are commonly used in stretch ceilings, a popular ceiling installation method in both residential and commercial properties. PVC ceiling films can be easily stretched and installed without the need for extensive construction work. They are ideal for creating smooth, seamless ceilings that conceal utilities and enhance the overall aesthetic of a room. Their ability to withstand different environmental conditions makes them particularly useful in kitchens, bathrooms, and other areas exposed to moisture.

In commercial settings, such as hotels, offices, and restaurants, PVC ceiling films are often used to create visually stunning, low-maintenance ceilings. The flexibility of the material allows for intricate designs and unique finishes that can add a touch of luxury to any space. Furthermore, PVC ceiling films provide sound insulation properties, contributing to a quieter and more comfortable environment.

The healthcare industry also benefits from the use of PVC ceiling films. Hospitals, clinics, and laboratories require ceilings that are not only durable but also easy to clean and maintain. PVC ceiling films, with their resistance to moisture and bacteria, offer a hygienic solution for these environments, ensuring both safety and comfort for patients and healthcare workers.

Shanghai MSD is committed to providing the highest quality PVC ceiling films to meet the diverse needs of customers. The company’s advanced manufacturing processes and quality control systems ensure that every roll of film is produced to the highest standards, providing reliable and long-lasting solutions for all ceiling applications.For more information on PVC ceiling films and their versatile applications, visit www.shanghaimsd.com .

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness