-

Fil d’actualités

- EXPLORER

-

Pages

-

Groupes

-

Blogs

-

Forums

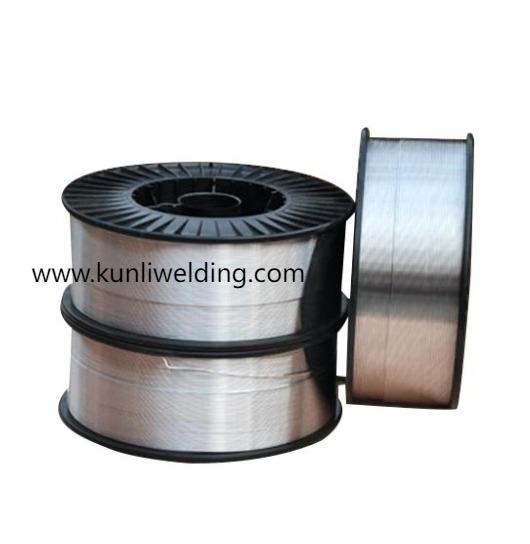

Kunliwelding ER5356: Magnesium Role in Weld Toughness

Rising fuel prices and stricter emission rules drive truck makers and ferry operators toward aluminum frames that shave tons off curb weight. Every welded joint must carry its share of the load without becoming the weak link. The secret hiding inside the most widely used aluminum filler metal lies in a few percent of magnesium that refuses to evaporate during the intense heat of the arc. Aluminum Welding Wire ER5356 owes much of its popularity to this simple but effective alloying strategy.

Pure aluminum melts and resolidifies softer than the original plate. Magnesium, however, dissolves into the aluminum lattice and stays there even after rapid cooling. This solid-solution strengthening mechanism directly raises both yield and ultimate tensile values of the deposited weld metal. Fabricators notice the bead does not sag or deform as easily when subsequent passes are laid or when heavy components are positioned on freshly welded assemblies.

Hardness tells a similar story. Standard aluminum filler metals often drop twenty to thirty Vickers points across the fusion zone. The magnesium that remains in solution counteracts that softening tendency, producing a deposited metal whose hardness profile more closely follows the heat-affected zone of common 6xxx and 5xxx base materials. The result shows up immediately on portable hardness testers used during procedure qualification and stays consistent from root to cap.

Age hardening plays no role here; the strengthening happens instantly as the weld pool solidifies. No waiting for natural aging or artificial heat treatment means production can continue without delays. Trailer manufacturers building high-cube van bodies particularly appreciate this immediate recovery when they weld long stringers that must resist road shock from day one.

Corrosion resistance also benefits indirectly. Magnesium that stays uniformly distributed reduces the chance of localized galvanic cells inside the weld metal itself. Truck frames splashing through winter road salt and ferry decks washed by seawater both see longer intervals before paint touch-ups become necessary.

Welders themselves feel the difference in puddle control. The magnesium lowers surface tension just enough to improve wetting without making the molten pool runny. Beads flow smoothly into corners and toe lines blend cleanly, reducing grind time before painting or anodizing. The same chemistry that strengthens the metal also stabilizes the arc, letting less experienced operators achieve acceptable profiles on position welding typical of chassis and hull construction.

Electric vehicle battery trays push the trend further. Thin 6xxx extrusions joined to cast nodes demand weld metal that matches extrusion strength while accepting the rapid cooling rates of robotic MIG. The proven magnesium level in ER5356 has become a default choice on many automotive lines because the deposited metal rarely becomes the low point in finite element calculations.

Bridge refurbishment projects replacing rusted steel decks with aluminum orthotropic panels face similar constraints. Weight limits on existing piers force designers to squeeze every possible kilogram. Welds that regain nearly full base-metal strength allow thinner cover plates and fewer stiffeners, keeping the new deck light enough to avoid expensive foundation upgrades.

Anyone specifying or purchasing aluminum filler metal can see these effects documented at www.kunliwelding.com . The site presents macro sections, hardness traverses, and tensile specimens taken from actual qualification coupons, all welded with Aluminum Welding Wire ER5356 straight from production spools. Clear photographs and straightforward explanations help engineers and purchasers understand exactly why the magnesium content continues to make this wire the everyday choice for structural fabrications that cannot afford soft welds.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness