Soton as Paper Straws Factory Leader

As plastic restrictions reshape global consumption, the demand for sustainable alternatives has transformed production landscapes. Behind every compostable straw lies a specialized Paper Straws Factory where material science meets environmental stewardship. These facilities operate beyond conventional manufacturing - they're innovation hubs converting renewable fibers into functional art. The process begins with responsibly sourced pulp, often from managed bamboo forests or agricultural residues, which undergoes purification to food-grade standards. This delicate alchemy requires balancing structural integrity with rapid biodegradability, ensuring products withstand hours in beverages yet decompose efficiently.

Water-based adhesives and plant-derived coatings replace synthetic sealants during forming. Temperature-controlled drying tunnels preserve dimensional stability while avoiding chemical accelerants. The true challenge emerges in quality validation: automated systems perform minute-by-minute checks for consistency in wall thickness, roll resistance, and liquid resilience. Facilities mastering this balance achieve the holy grail - straws maintaining rigidity in iced drinks for hours while breaking down in soil within months.

Operational sustainability defines leadership. Progressive factories implement rainwater harvesting for production cycles and solar arrays powering precision machinery. Waste pulp becomes packaging filler or community compost, while steam exhaust feeds greenhouse operations. Such circular systems minimize external resource dependence while creating local economic opportunities near raw material sources.

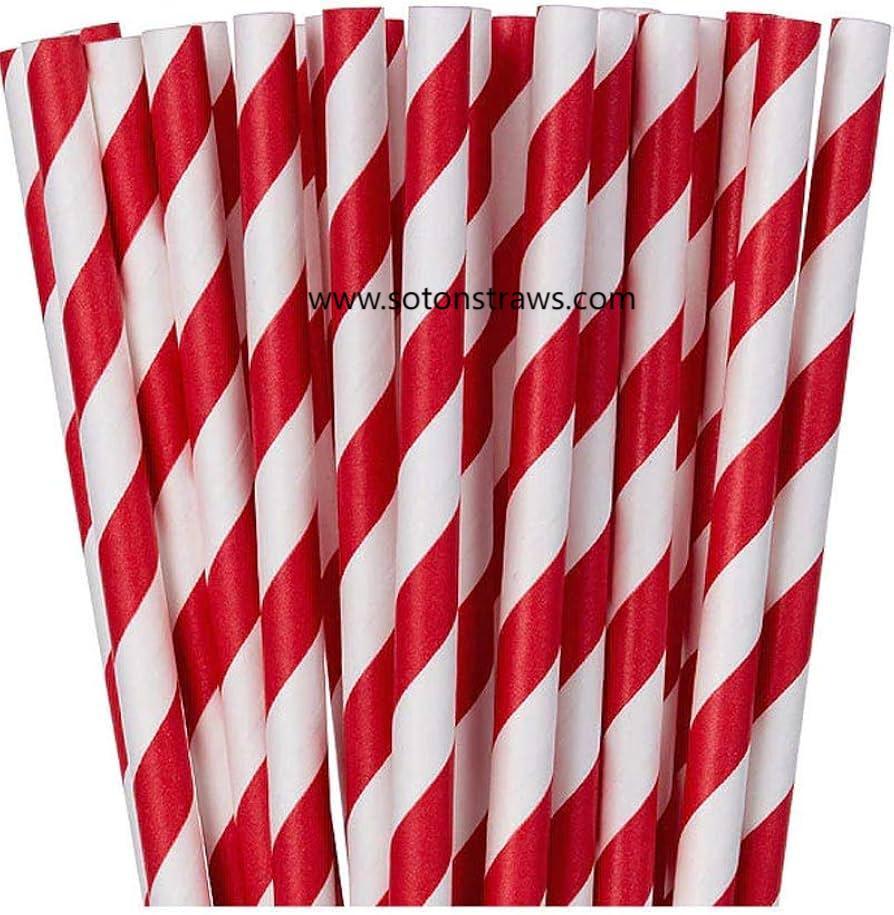

A forward-looking Paper Straws Factory also pioneers application-specific solutions. Custom embossing patterns enhance grip for children's drinks, while extra-thick walls suit bubble teas. Water-resistant variants for tropical resorts and extra-long designs for cocktail bars demonstrate adaptive manufacturing capabilities. This versatility helps cafes, airlines, and stadiums maintain brand identity during sustainability transitions.

Soton embodies this integrated approach through continuous innovation. Our facility's closed-loop water system and biomass energy conversion set new benchmarks for clean production. Proprietary fiber-blending techniques create signature textures - from silky-smooth for premium venues to subtly flecked artisan options. Every batch undergoes simulated real-world testing, from cola immersion trials to compost decomposition tracking. Partner with Soton to transform single-use items into statements of ecological integrity, where every straw carries our commitment to planetary stewardship.Click https://www.sotonstraws.com/product/ to reading more information.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness