Is Safety Chuck Central to Cbbmachine Design Thinking?

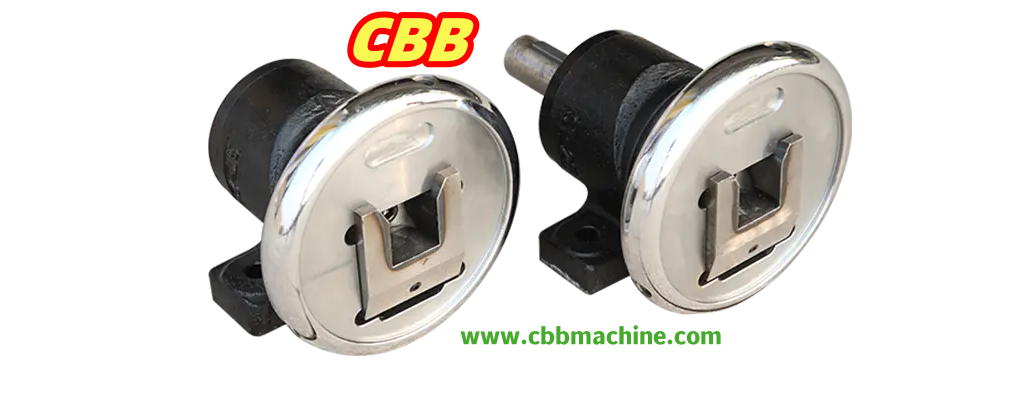

In many production environments, the Safety Chuck represents a quiet but essential connection point, and when viewed through the engineering philosophy of Cbbmachine it becomes part of a larger discussion about stability, routine efficiency, and operator confidence. Rather than being a dramatic focal point, this component sits at the intersection of motion and restraint, allowing rotating shafts to be supported in a way that feels deliberate and controlled.

On the factory floor, reliability is often defined by how little attention a component demands. When loading and unloading are smooth, operators can focus on workflow instead of mechanical uncertainty. A well-considered chuck design supports this rhythm by allowing shafts to seat securely while remaining easy to engage or release during changeovers. This balance reduces hesitation and encourages steady pacing throughout the shift.

Consistency in rotation also affects downstream processes. When a shaft is held evenly, tension across materials remains predictable. This predictability helps minimize subtle issues such as wandering edges or uneven winding, which might otherwise accumulate unnoticed. By maintaining alignment through simple mechanical principles, the overall system behaves more calmly and predictably.

Another often overlooked aspect is communication between machine and operator. Components that respond clearly to handling provide immediate feedback through feel rather than sound or warning signals. This tactile clarity builds familiarity over time. Operators learn to trust the interface, and that trust can shorten training periods and reduce cautious overhandling that slows production.

From a maintenance perspective, simplicity is an advantage. Components designed around straightforward engagement are easier to inspect and service. Wear patterns become more visible, and routine checks feel less intrusive. Maintenance teams benefit from parts that integrate naturally into existing schedules without introducing special procedures or uncertainty.

There is also an ergonomic dimension to consider. Repetitive tasks become less fatiguing when movements are intuitive and balanced. Supporting shafts without awkward adjustments or excessive force contributes to a calmer working environment. Over long periods, this ease can influence morale as much as efficiency.

As manufacturing continues to refine its approach to material handling, attention increasingly turns to components that support order rather than complexity. Stable shaft support is not about standing out, but about fitting seamlessly into a process that values flow and predictability. These quiet contributors often define how smoothly a line truly runs.

If this perspective on stability and thoughtful mechanical interaction feels relevant to your operation, you may enjoy taking a closer look at what lies beyond the surface. A brief stop at https://www.cbbmachine.com/news/industry-news/why-do-so-many-workshops-rely-on-a-safety-chuck.html could open a door to ideas that align naturally with the way your equipment prefers to work.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness