Heat Pump Repair Services: Understanding Common Issues and Best Practices

Heat pump repair services have become increasingly important as more households rely on heat pumps for year-round heating and cooling. Heat pumps are versatile systems that transfer heat between a home and the external environment, providing energy-efficient climate control. However, like all mechanical systems, they can encounter performance issues that require repair and maintenance. Understanding common problems, their causes, and effective solutions helps homeowners ensure comfort, efficiency, and longevity of their systems. Proper attention to repair needs can prevent energy waste, inconsistent temperatures, and costly replacements.

Concept Explanation

What Heat Pump Repair Services Include

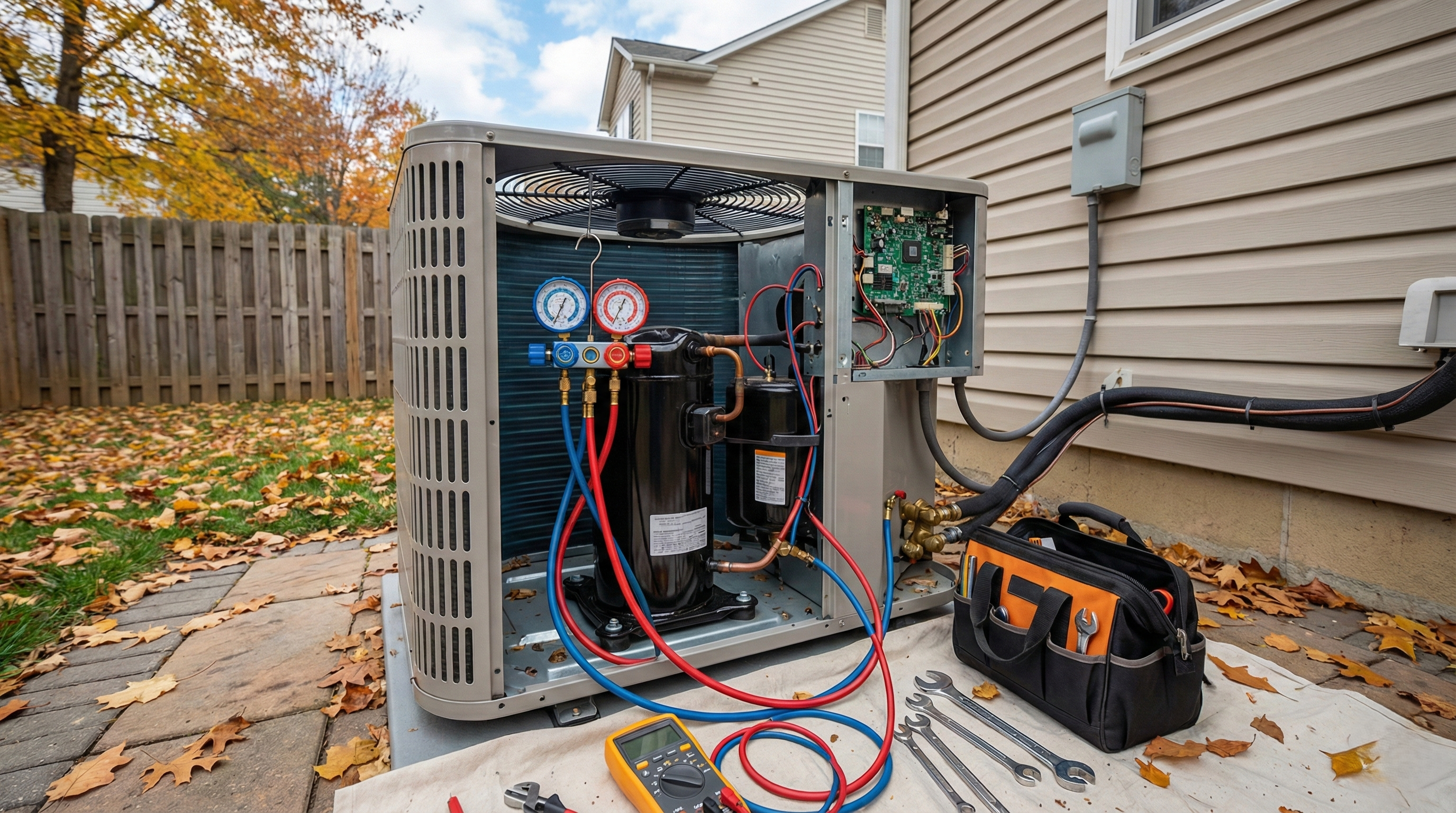

Heat pump repair services cover a range of troubleshooting and corrective measures designed to restore system efficiency. This includes identifying malfunctioning components, fixing refrigerant leaks, calibrating thermostats, resolving electrical issues, and ensuring the system operates safely. Repair services may also involve cleaning or replacing worn parts, addressing airflow issues, and performing system diagnostics.

How Heat Pumps Function

Heat pumps operate by transferring heat rather than generating it, using a refrigerant cycle and compressor system. In heating mode, they extract heat from the outside air (or ground) and transfer it indoors. In cooling mode, the process is reversed, moving heat from inside the home to the exterior. Efficiency and performance rely on properly functioning components, accurate refrigerant levels, and correct airflow.

Common Misunderstandings About Heat Pump Repairs

Many homeowners assume heat pumps function identically to traditional HVAC systems and that repairs are simple. In reality, heat pumps involve refrigerant systems, electrical components, and complex controls. Attempting DIY repairs without technical knowledge can worsen damage, create safety hazards, or void warranties.

Common Problems and Issues

Heat pumps can experience a variety of problems over time. Some of the most common include:

-

Insufficient heating or cooling output

-

Ice formation on the outdoor unit

-

Unusual noises, such as rattling or grinding

-

Increased energy bills despite normal usage

-

Frequent cycling on and off

-

Thermostat or control malfunctions

These issues often stem from installation errors, wear and tear, environmental factors, or neglect of routine maintenance.

In-Depth Breakdown of Repair Issues

Reduced Heating or Cooling Performance

When a heat pump does not maintain the desired temperature, it may indicate refrigerant leaks, blocked airflow, or malfunctioning compressors. Low refrigerant levels reduce heat transfer efficiency, while dirty filters or obstructed ducts prevent adequate airflow.

Ice Formation on the Unit

Frost or ice on the outdoor unit is a common sign of airflow restrictions, low refrigerant, or failing defrost cycles. While some ice formation is normal in cold weather, persistent or excessive ice reduces efficiency and can damage components.

Unusual Noises

Squealing, grinding, or rattling noises may indicate worn bearings, loose panels, or fan motor issues. Addressing these sounds promptly can prevent further mechanical damage.

Frequent Cycling

Short cycling, where the heat pump turns on and off repeatedly, is often caused by improper sizing, thermostat issues, or refrigerant imbalances. This behavior increases energy consumption and accelerates wear on components.

Electrical or Control Malfunctions

Faulty wiring, damaged sensors, or malfunctioning control boards can disrupt normal operation. These issues require professional diagnostics to prevent system failures or safety risks.

Why These Problems Occur

Environmental Factors

Extreme temperatures, high humidity, and seasonal changes can stress heat pump components. Ice formation, condensation, and temperature fluctuations affect efficiency and may trigger repair needs.

Mechanical Wear and Aging

Components like compressors, fans, and valves experience wear over time. Regular use without maintenance accelerates deterioration, leading to failures or reduced performance.

Installation or Design Issues

Incorrect installation, such as poor ductwork, improper refrigerant charge, or misaligned units, contributes to recurring issues. Even high-quality systems underperform if installation is flawed.

Neglect of Maintenance

Skipping routine inspections, filter replacements, or system cleaning allows debris buildup and unnoticed minor problems to escalate into major repairs.

Preventive Measures and Best Practices

Proper care can reduce the likelihood of major repairs. Best practices include:

-

Scheduling annual professional inspections and tune-ups

-

Regularly changing air filters to maintain airflow

-

Ensuring outdoor units are free from debris and obstructions

-

Monitoring system performance and unusual noises

-

Keeping thermostat settings consistent to prevent strain on components

Preventive maintenance ensures heat pumps operate efficiently, extend lifespan, and minimize unexpected repair costs.

When Professional Help Is Needed

Professional repair services are necessary when:

-

Refrigerant leaks are suspected, requiring certified handling

-

Electrical components or wiring issues are present

-

The compressor or fan motors fail

-

Ice accumulation persists despite defrost cycles

-

Noise or performance issues cannot be resolved through basic maintenance

Professional intervention ensures safety, compliance with regulations, and accurate diagnosis of complex problems.

Long-Term Impact if Ignored

Ignoring heat pump issues can result in:

-

Decreased energy efficiency and higher utility costs

-

Uneven heating or cooling, compromising comfort

-

Accelerated wear and reduced system lifespan

-

Potential damage to electrical components or compressors

-

More costly repairs or full system replacement

Addressing repair needs promptly helps preserve performance and avoid unnecessary expenditures.

Conclusion

Heat pump repair services are essential for maintaining reliable, efficient, and safe climate control in homes. Timely identification of issues, proper maintenance, and professional repairs support system longevity and energy efficiency. Experts like Dr Kool Air Conditioning emphasize that understanding common problems and taking preventive measures ensures that heat pumps continue to provide consistent comfort throughout the year.

Frequently Asked Questions (FAQs)

How often should a heat pump be serviced?

Heat pumps should be professionally inspected at least once a year, ideally before peak heating or cooling seasons.

Can I repair a refrigerant leak myself?

No. Handling refrigerants requires certification and specialized equipment. DIY attempts can be unsafe and damage the system.

Why is my heat pump making a loud noise?

Loud noises may result from loose components, fan motor issues, or worn bearings. Prompt inspection prevents further damage.

What causes ice to form on a heat pump?

Ice forms due to restricted airflow, low refrigerant, or a malfunctioning defrost cycle. Excessive ice should be addressed by a professional.

How long do heat pumps typically last?

With proper maintenance, most heat pumps last 12–15 years. Regular inspections and timely repairs extend system life.

Here, you can find more articles.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness