-

Fil d’actualités

- EXPLORER

-

Pages

-

Groupes

-

Blogs

-

Forums

Protective Gear Double Wall Features

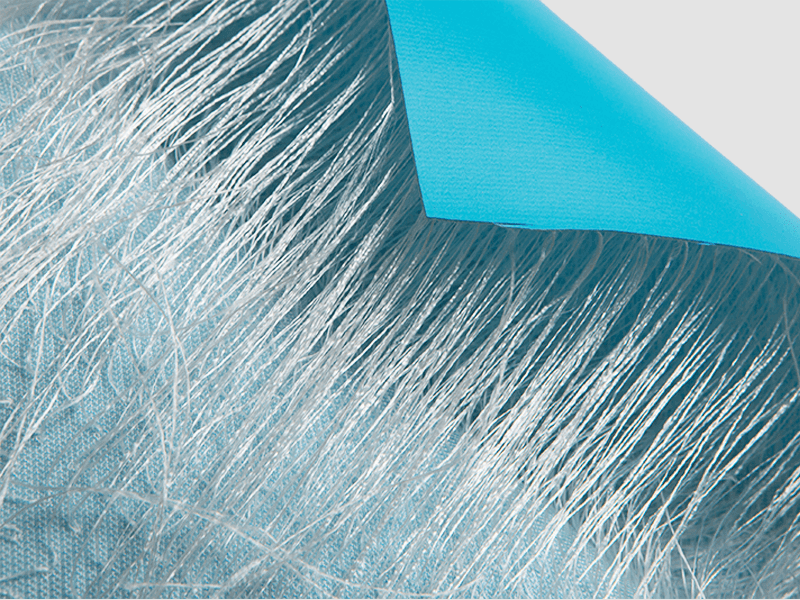

Industrial workplaces and high-risk activities demand robust protective materials that balance safety with wearer comfort, where the Double Wall Fabric excels through its multi-layer spacer design that integrates impact absorption, thermal protection, and enhanced durability in demanding operational settings. This specialized textile features two tough outer layers—typically woven from high-tenacity polyester or aramid blends—linked by dense vertical yarns that create a resilient cushioning zone, capable of dissipating force from blunt impacts while maintaining breathability to reduce heat stress during extended shifts.

Impact resistance is achieved through the compressible air layer, which deforms under load to spread energy across a wider area, significantly lowering peak force transmission compared to single-layer fabrics. Thickness variations from 8mm to 30mm allow tailoring for specific hazard levels, with denser spacer yarns in high-risk zones providing progressive stiffness. Reinforcement with cut-resistant fibers or ballistic-grade inserts elevates protection against sharp objects or projectiles in specialized variants.

Thermal and flame protection stem from inherent air insulation combined with fire-retardant coatings or inherently flame-resistant yarns such as modacrylic or para-aramid, meeting standards like EN 11612 or NFPA 2112 for heat and flame exposure. The open structure promotes airflow, lowering the risk of heat-related illnesses by facilitating sweat evaporation even under impermeable outer shells. Chemical splash resistance is enhanced via fluorocarbon or silicone treatments that repel oils, acids, and solvents without clogging ventilation channels.

Manufacturing for protective applications utilizes heavy-duty raschel or double-needle bar warp knitting machines engineered for high yarn tension and precise spacer control, producing wide rolls that minimize seams in final garments. Base yarns are pre-treated for dye affinity and shrink resistance before knitting, ensuring color fastness after repeated industrial laundering.

Post-knitting processes include multi-stage coating with breathable PU membranes for liquid barriers, applied via direct or transfer methods to preserve softness. High-visibility pigments or reflective strips are integrated during dyeing or via thermal transfer for compliance with visibility standards like EN ISO 20471. Rigorous testing encompasses abrasion cycles per Martindale, tear propagation strength, and dimensional stability after exposure to heat or chemicals.

In firefighting turnout gear, double wall fabric serves as thermal liners beneath moisture barriers, providing critical seconds of protection while allowing moisture escape to prevent steam burns. Welding blankets and aprons incorporate heat-reflective versions that shield workers from sparks and molten metal splatter in foundries and shipyards.

Construction and mining safety vests utilize padded spacer zones over shoulders and elbows to cushion falls or impacts from tools, combined with high-visibility coloring for site safety. Law enforcement and military tactical vests integrate the fabric as trauma pads or ventilation layers under hard armor plates, improving comfort during prolonged wear.

Agricultural and forestry workers benefit from chainsaw-protective pants featuring multi-layer blocking systems where the spacer structure jams cutting chains upon contact. Chemical handling suits employ sealed-seam constructions with double wall fabric cuffs and collars that maintain dexterity while containing spills.Shanghai Ming Shida International Trade Co., recognized for durable PVC-coated and technical textiles including advanced spacer fabrics, supplies double wall fabric variants engineered for industrial safety and protective equipment. Find out more about their suitability for diverse protective needs at https://www.shanghaimsd.com/news/why-is-double-wall-fabric-an-ideal-choice-for-multiple-applications.html .

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness